-

DP 12-10 (DaNiuDi)Abstract:

Top Well and BJ SERVICES teamed up to provide assistance to a customer after a casing fracture treatment had sanded off leaving over 800 meters of sand inside the well.

Details

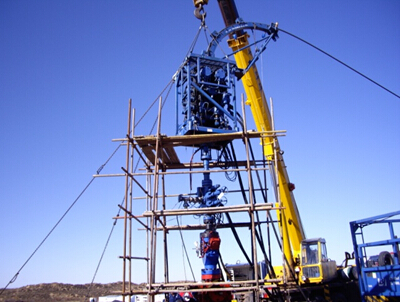

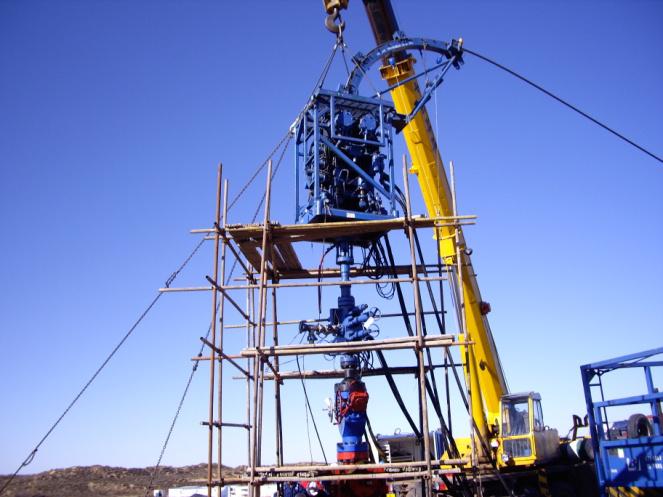

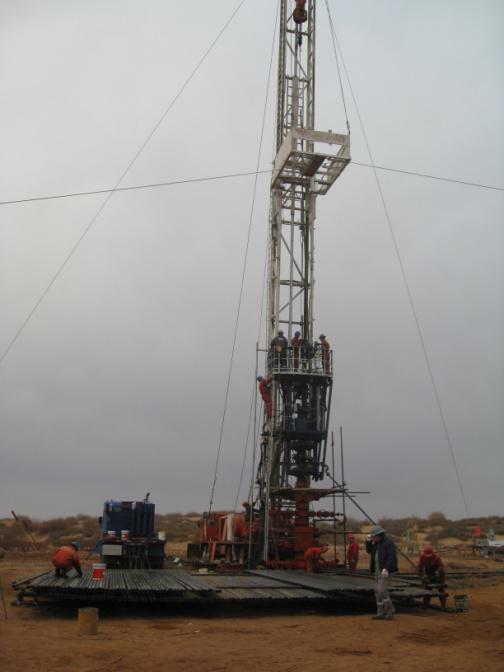

Top Wells S-9 Snubbing Unit BJ Services Coil Tubing Unit

Synopsis: Clean out Sand and Deploy Production String

Well Data:

- Tubing: 60.3mm (2.375”)

- Casing: 177mm (7”)

- Max Pressure: 26 Mpa (3770 Psi)

- Well Depth: 4000 Meters (13,123’)

In 2007, Top Well and BJ SERVICES teamed up to provide assistance to a customer after a casing fracture treatment had sanded off leaving over 800 meters of sand inside the well. Top Wells crews assisted BJ services to rig in a coil tubing unit and both an N2 and water pumping unit in order to wash the sand out of the well bore.

The wellhead was taken off at the tubing spool and a flow cross and single gate rams dressed with blind ram fronts were installed prior to rigging in the coil tubing unit. The tubing hanger was plugged and installed into the tubing spool. The blind rams were then pressure tested to 70 Mpa (10K). Once the pressure testing was complete, the tubing hanger was removed and the blind rams closed and locked. The coil tubing unit was then rigged in and the clean out performed.

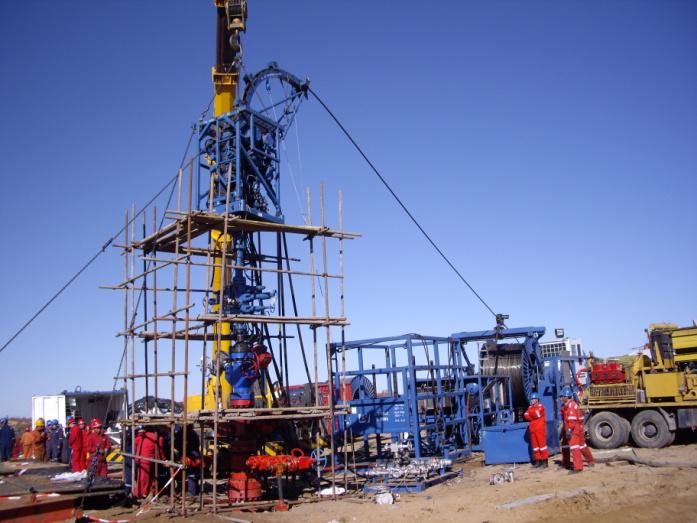

Once the well bore was cleaned out, Top Well assisted BJ Services to rig out their equipment and the full primary BOP stack and the S-9 snubbing unit rigged in.

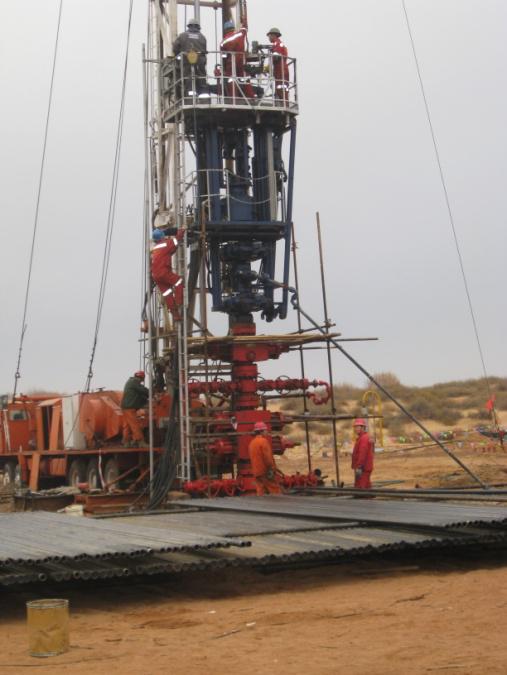

Top Wells S-9 Snubbing in Tubing

A Top Well knock out style plug was placed on the bottom of the string and the snubbing unit snubbed and stripped in the 60.3mm (2.375”) production string. The tubing hanger was staged in and landed. The snubbing unit and BOP stack was rigged down and the wellhead nippled up.

An N2 pumping unit was then used to pressure up on the tubing and blow the knock out plug off the end of the tubing.

N2 Pumper Expending Knock Out Plug