-

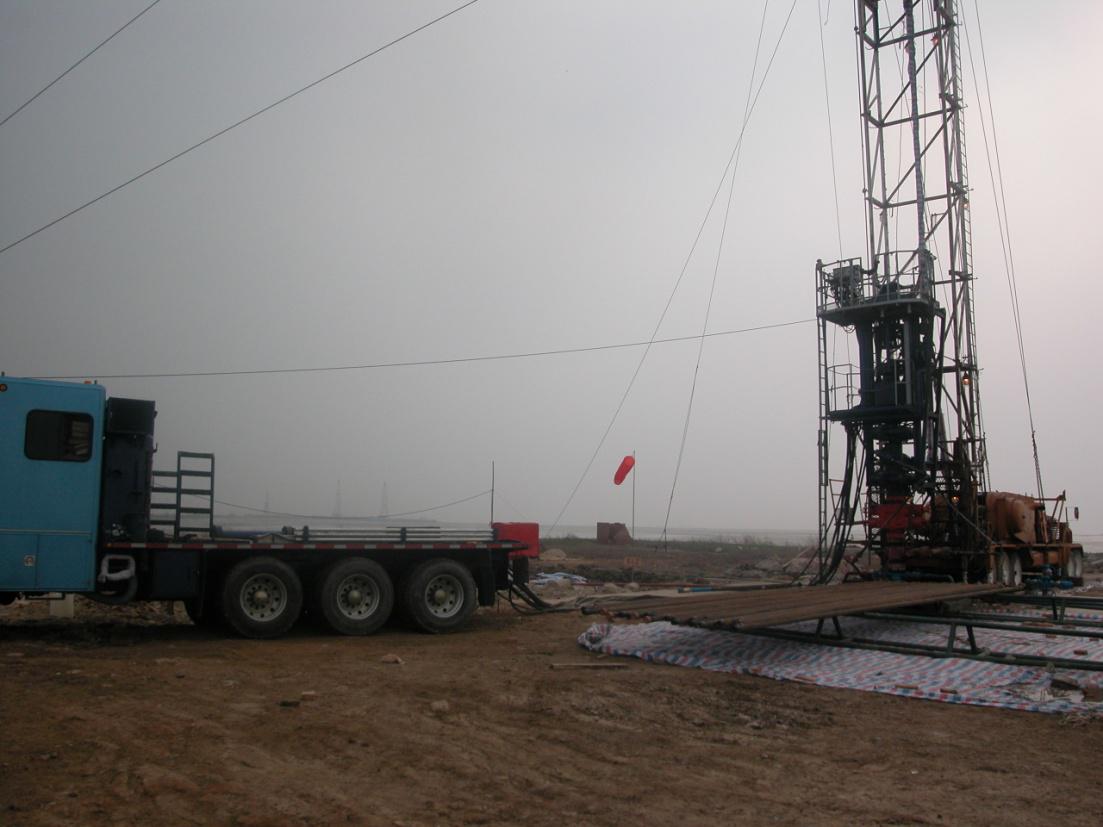

BAN 9-01-X1 (Dagang)Abstract:

Petro China contacted Top Well regarding their options to permanently abandon a well that had been suspended with a 45 meter (150’) cement plug just 50 meters (165’) from surface.

Details

Synopsis: Drill Pilot Hole Through Surface Cement Plug

Well Data:

- Tubing: 60.3mm (2.375”)

- Casing: 139mm (5.5”)

- Max Pressure Possible: 26 Mpa (3770 Psi)

- Well Depth: 3000 Meters (9850’)

In 2006, Petro China contacted Top Well regarding their options to permanently abandon a well that had been suspended with a 45 meter (150’) cement plug just 50 meters (165’) from surface. There was a very real concern that since the plug had been placed, the potential for trapped pressure underneath the plug could eject the pipe from the hole if conventional workover methods were utilized.

After consulting with the Top Well team, a plan was conceived to utilize one of our snubbing units in conjunction with a down hole motor to drill into the cement and relieve any trapped pressure. By using the snubbing unit, total pipe movement control was possible, as well as added benefit of being able to induce weight on the string for drilling up the cement so close to surface.

The wellhead was removed above the tubing spool, and a double gate 70 Mpa (10K) double gate BOP installed. The top cavity was dressed for 60.3mm (2.375”) tubing and the bottom cavity dressed with blind rams. The BOPs were pressure tested to 35 Mpa (5K) and then the snubbing unit was rigged up.

The BHA was made up as follows:

From the bottom up:

- 114 mm (4.5”) tri cone bit

- 114mm (4.5”) OD Bit sub

- 114mm (4.5”) OD Float Sub (c/w Dart float installed)

- 114mm (4.5”) OD Float Sub (c/w Dart float installed)

- PDM motor

- Crossover

- 60.3mm (2.375”) tubing to surface.

Although this well had no pressure on it, Petro China used prudence by utilizing the snubbing unit for safety reasons, and therefore minimizing risks for the crews involved.